High-Precision Infrared Detection Payload (Visible Light) RK-ZH1071

Category:

Product Details

- Product Description

-

RK-ZH1071 (Visible Light) is a high-precision UAV-mounted detector that integrates infrared and visible light lenses. The high-sensitivity infrared core enables high-precision temperature measurement, with temperature consistency reaching ±0.5°C. The dual-light integrated gimbal can quickly and accurately acquire the surface temperature and high-definition images of the target object without getting close. Integrated with AI intelligent recognition algorithm, it automatically identifies and extracts the temperature of the measured equipment, achieving real-time, fast, and accurate equipment detection and timely identification of potential hazards. Automatic focusing improves detection efficiency and significantly enhances imaging quality and temperature measurement accuracy.

Product Features

High Precision: Temperature measurement accuracy better than ±2°C or ±2%

Real-time: Built-in temperature and humidity sensor, real-time calculation of the temperature of the device under test

AI Intelligent Recognition: Integrates AI algorithm model to achieve target recognition, automatic inspection, and automatic extraction of the temperature of the device under test

Technical Parameters

High-precision Infrared Camera

Resolution

640X512

Field of View

25°X19°

Focal Length

25mm

Spatial Resolution

0.68mrad

Spectral Range

7.5um~14um

Temperature Measurement Method

Point temperature measurement, area temperature measurement

Visible light camera configuration/ Starlight night vision camera configuration

Effective Pixels

8.51 million Optical Zoom

20X Resolution

3840x2160 Field of View

4.1°-70.2° CMOS

1/2.5-inch Exmor RTM Focal Length

4.4mm-88.4mm mm Laser Rangefinding

Wavelength

900nm

Measurement Range

1-100m

Other Parameters

Gimbal

XPORT

Weight

1.3kg

Power Consumption

11W

Protection Level

IP45

Operating Temperature

-20℃ to 50°C

Computing Power

6T

Supported Models

M350 RTK

Shooting Function

Interlocking Photography

AI-assisted photography for autonomous drone inspection

This system integrates AI edge computing, lightweight and pruning optimization of network AI models, automatic camera control, intelligent sensing exposure, and AR technologies into an edge computing intelligent system. It is a suite of auxiliary tools for autonomous drone inspection tasks. Without changing existing drone equipment, flight path results, inspection APP operation processes, and usage habits, it can be quickly and easily integrated into existing APP software, enabling real-time flight path AR inspection, high-precision AI-assisted image capture, automatic control of gimbal cameras, and intelligent sensing exposure functions. It is compatible with all DJI industry RTK models and 35kV-1000kV voltage level line inspections.

1. AR inspection of autonomous drone inspection routes; built-in AR augmented reality technology, real-time display of the spatial relationship between the route and the towers.

2. AI-assisted photography technology service for real-time target recognition during autonomous drone inspection; supports real-time target detection application scenarios and can perform high-precision identification of typical power targets such as cross-arm hanging points, insulator strings, conductor hanging points, and ground wire hanging points.

3. Automatic zoom and autofocus of the inspection targets during autonomous drone inspection.

4. Real-time scene judgment capability at the front end of autonomous drone inspection and intelligent exposure compensation.

Intelligent Management Platform

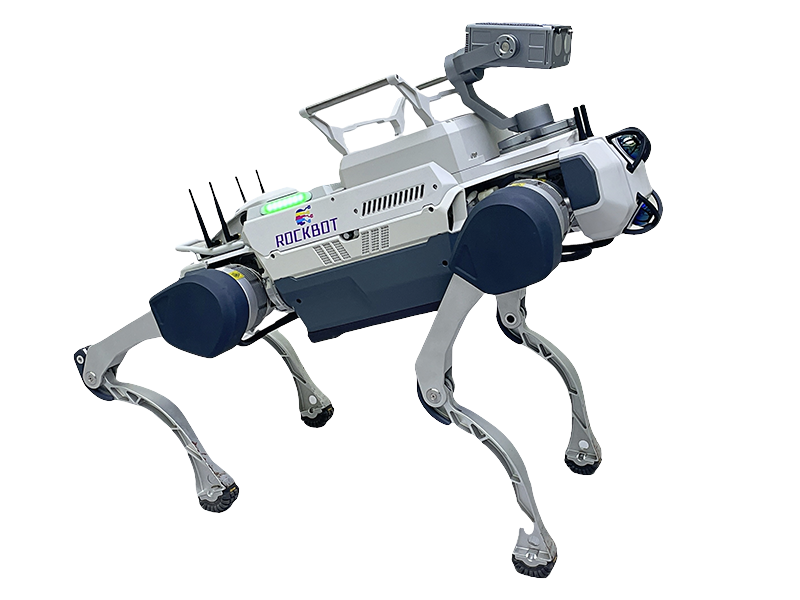

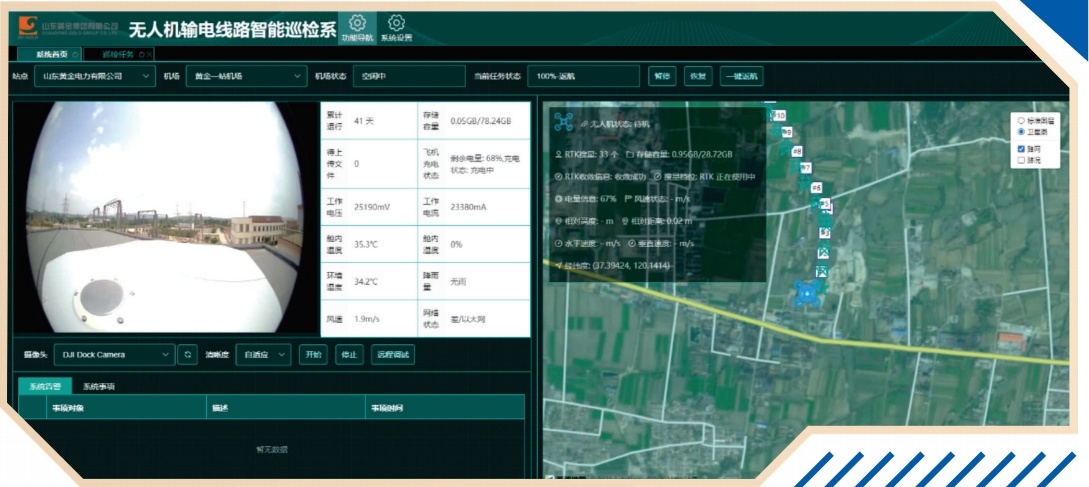

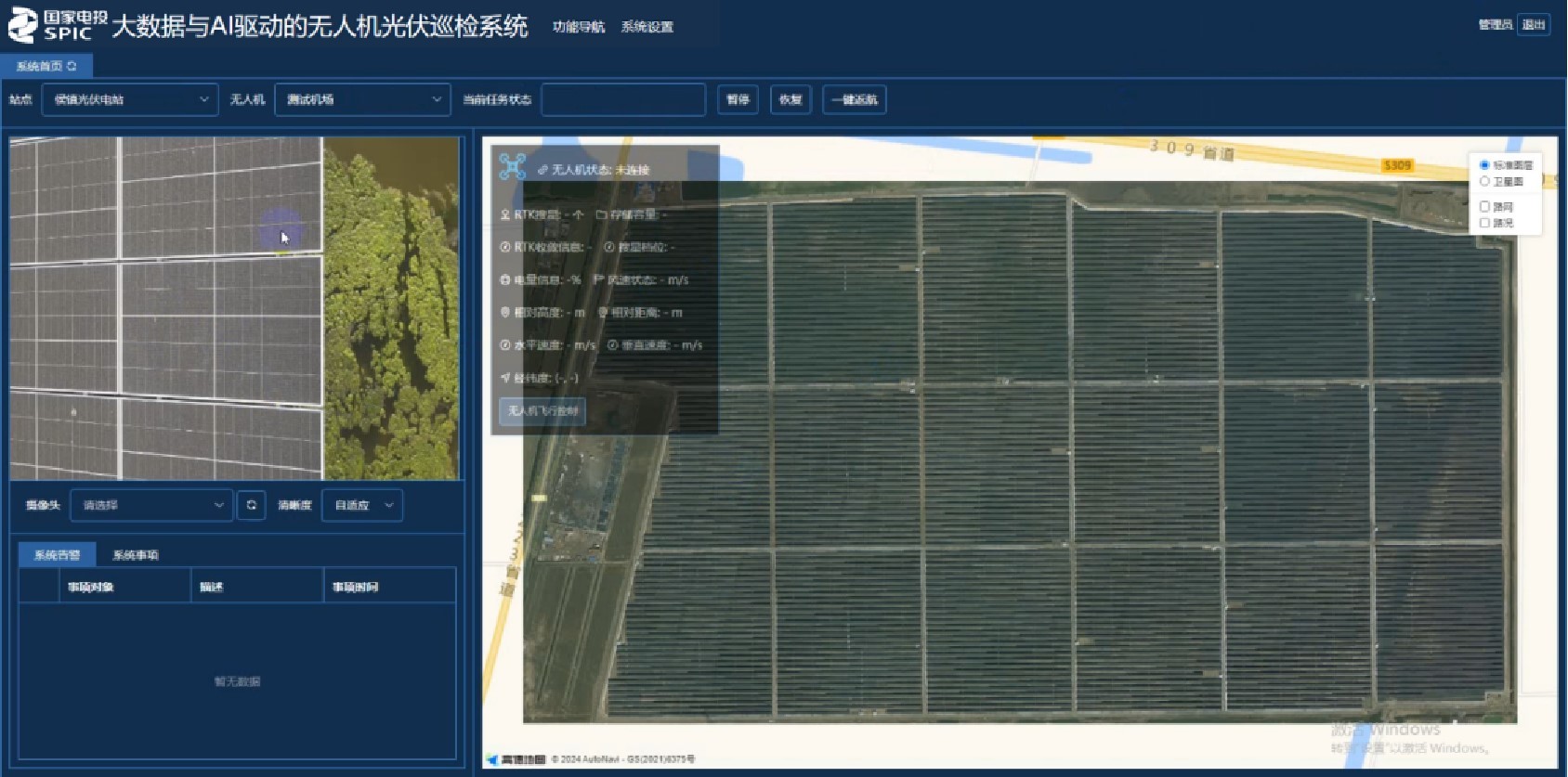

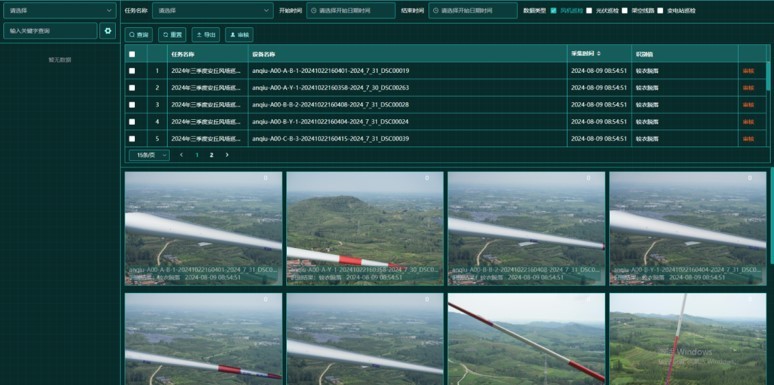

The RK-MP autonomous drone inspection and control platform is a data control, AI image recognition, and big data value mining application system specifically designed for drones and nest inspections. It is mainly used for intelligent operation and maintenance of drones and nests, achieving systematization and intelligence on the platform. Through three-dimensional visualization and full-process control, it realizes the interconnection of data between the field and the backend, forming a complete closed loop for drone inspection work, improving inspection efficiency, improving data analysis efficiency, enhancing data control application levels, and achieving standardized management of results.

Unifying the management of enterprise resources, operation and maintenance equipment, planned tasks, machine inspection results, and line defects, realizing real-time sharing and three-dimensional visualization of resource results, full life cycle management of equipment, and functions such as big data statistical analysis and early warning; the platform, together with the flight control module and nest control module, constitutes a complete operation and maintenance solution, integrating big data, artificial intelligence, the Internet of Things, and cloud computing technologies.

|

Drone Product Series |

||

|

|

|

|

|

DJI M30T |

M300 Drone Mobile Nest Vehicle |

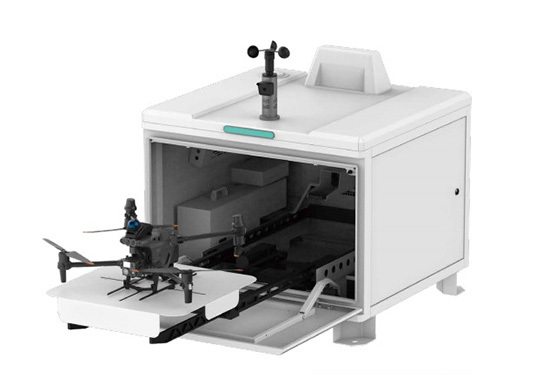

Drone Nest |

Drone Photovoltaic Inspection System

Drone Wind Turbine Inspection System

Drone Power Line Inspection System

|

On-site Operation Demonstration |

|||

|

|

|

|

|

|

High-altitude Snow Mountain Operation |

Mountainous Forest Land Operation |

Mountainous Area Operation |

Distribution Network Inspection |

|

|

|

|

|

|

Gobi Desert Operation |

Gobi Desert Operation |

Forest Area Operation |

Desert Operation |

Product Categories